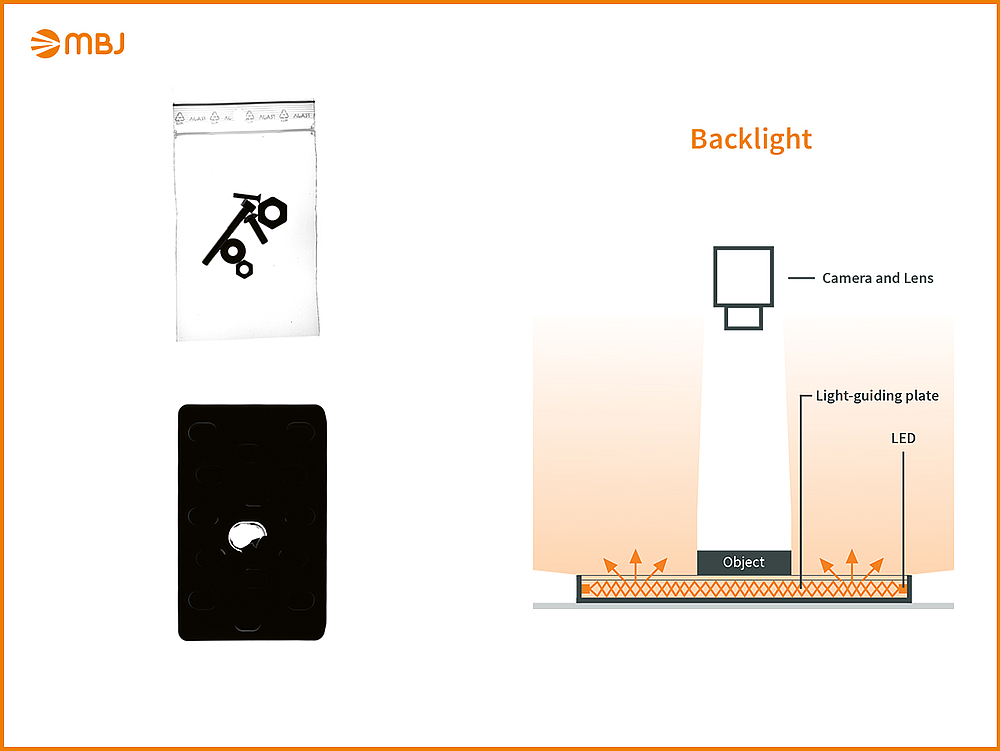

Backlight

For the backlight application, the lightis placed under or behind the test object. The object itself appears dark and creates a shadow or outline image. In the case of (partially) transparent objects, the background illumination can be used to assess inclusions or fill levels. Diffuse and homogeneous radiation of the light is important to ensure the best possible image quality.

Transmitted light illumination is ideal for:

- Inspecting and measuring contours

- Presence/position control of objects

- Detection of inclusions

- Level control

At MBJ, we rely on sided-fired LEDs for our backlights, which ensures maximum diffusion and homogeneity of light emission.

open Backlight

open Flexlight Back

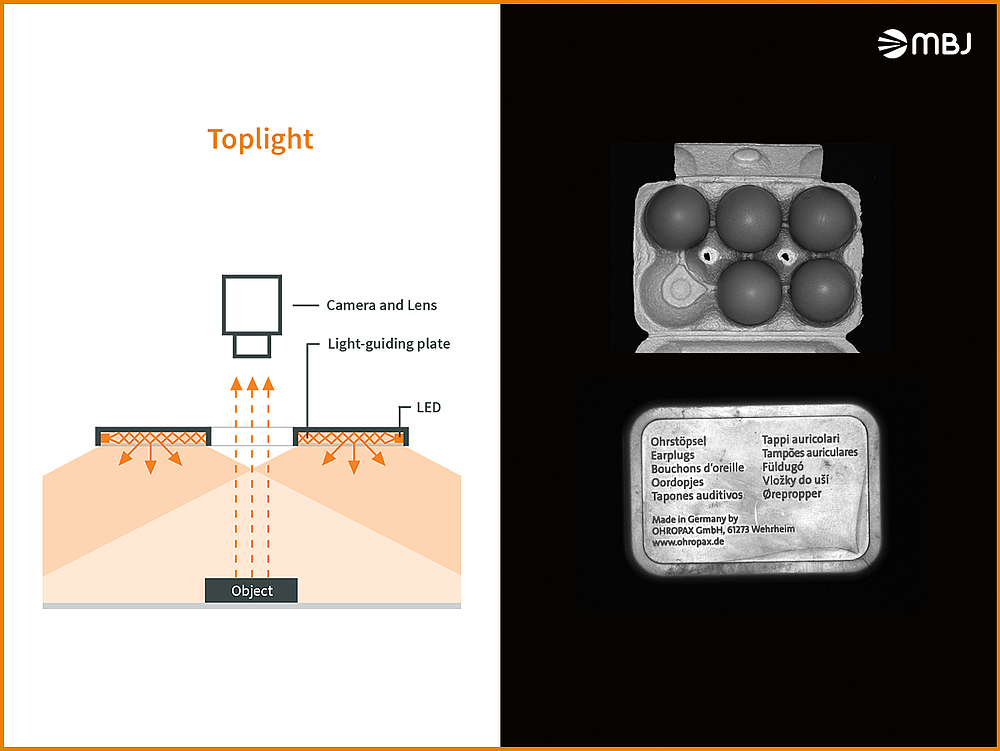

Toplight

The diffuse toplight with camera opening is ideal for inspecting objects in brightfield with few reflective surfaces. Depending on the test object, it may be useful to adapt the toplight with polarization foils or other light manipulations to achieve an optimum test result.

Suitable for:

- A wide variety of measurement and inspection tasks

- Presence control

- Low reflective to matte surfaces

The MBJ toplights work with lateral coupling of the LED light, which ensures a highly diffuse, very homogeneous radiation over the entire illuminated surface.

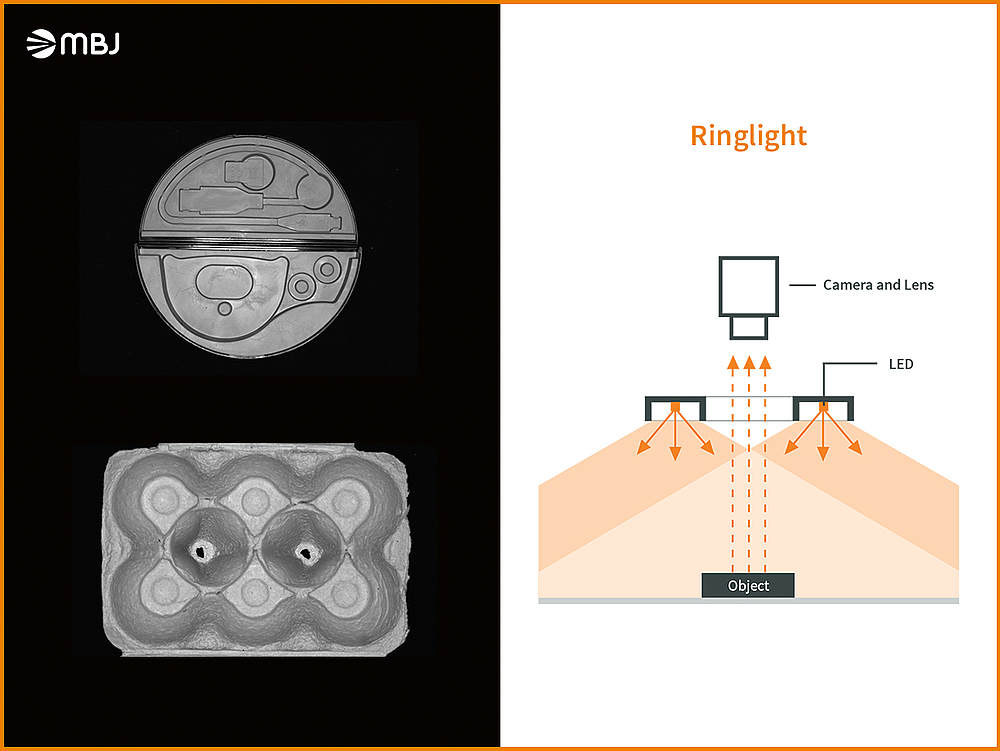

Ringlight

Ringlights are probably the most typical toplighting illuminators and are very versatile as well as easy to use. The illumination from around the lens opening minimizes hard object shadows. The focus of this light is on homogeneous and bright illumination of the surface. Ring lights are not suitable for highlighting surface defects or three-dimensional structures. For larger distances or highly absorbent objects use High Power Ringlights.

- Direct light emission

- Area illumination of rather matte surfaces

- Suitable for two-dimensional inspection tasks such as print or position control, round objects

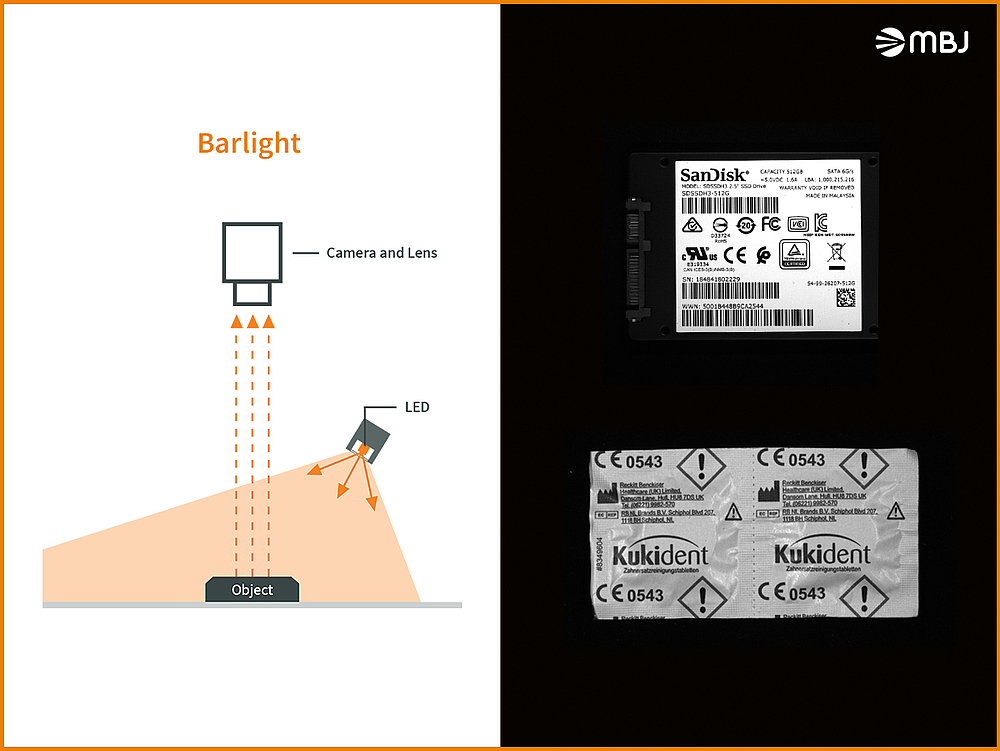

Barlight

Barlights can be used in a variety of ways. For brightfield applications, almost any illumination angle can be realized and, with a flat angle in regard to the object, darkfield applications are possible. Using optical foils, barlghts can also be used for simple line applications or with diffusers are suitable for backlighting.

Especially when there is uncertainty as to how best to highlight the object properties to be inspected, the use of barlights is recommended. Different illumination angles, the use of multiple barlights to ensure uniform illumination and a wide range of sizes ensure maximum flexibility.

- Can be used individually or as a combination of several barlights

- Flexibility in illumination angle

- Suitable for almost all inspection tasks

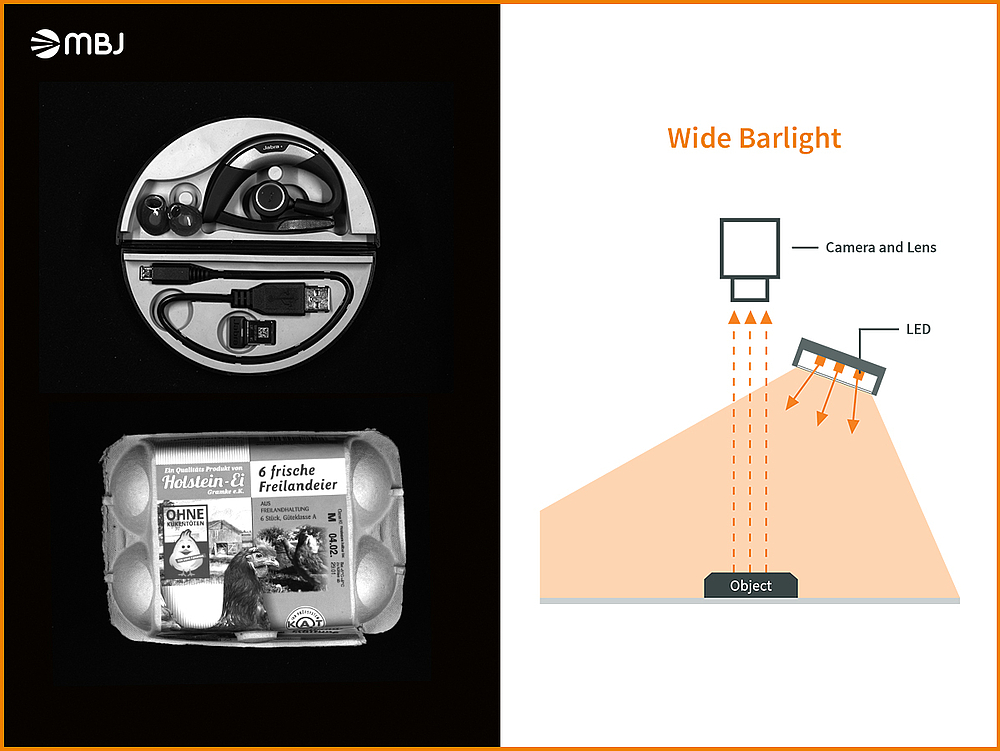

Wide Barlight

The use of wide barlights offers the same flexibility as barlights, but can illuminate larger objects or provide more area lighting due to a larger illuminated area. Light intensity can be maximized through the use of high power barlights. These are also recommended for larger working distances.

- Larger objects, wide-area illumination

- Larger working distances

- Wide range of inspection tasks and illumination angles

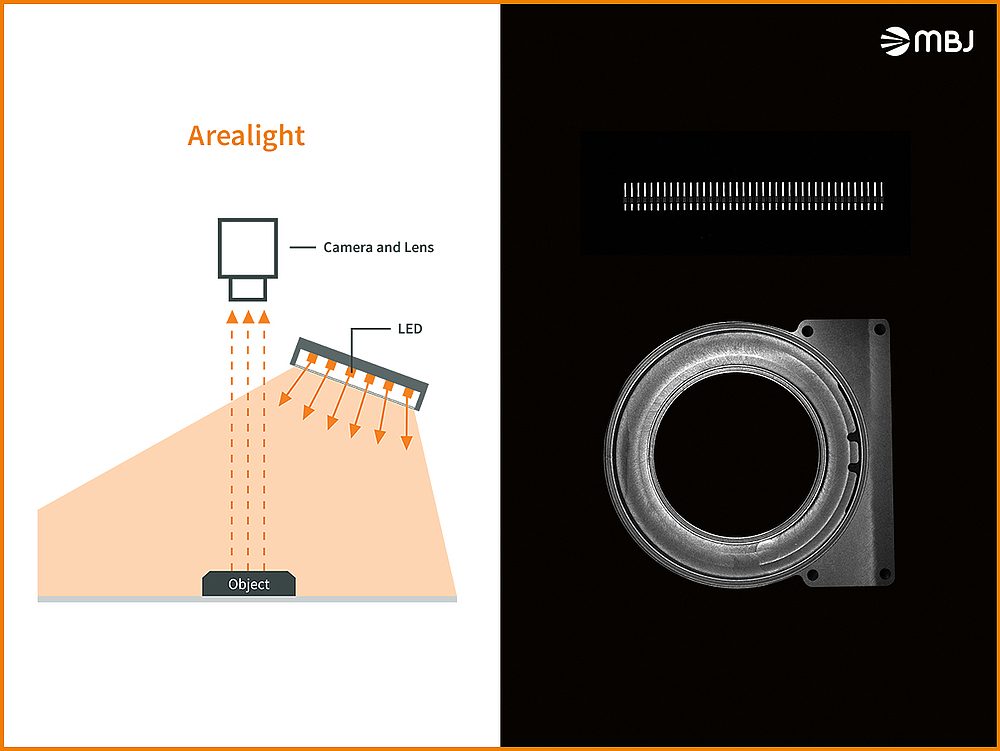

Arealight

These large arealights with direct light emission are suitable for illuminating large, flat objects uniformly and brightly, with less focus on illuminating details. Different illumination angles of the lights to the test object allow tuning to the object property to be tested. Typically, the area lights are used as incident light for brightfield or partial brightfield applications. They can be used individually or in combination, e.g. to prevent the formation of shadows.

- Detection of surface defects

- Position control of large objects

- Compensation of influences of ambient light

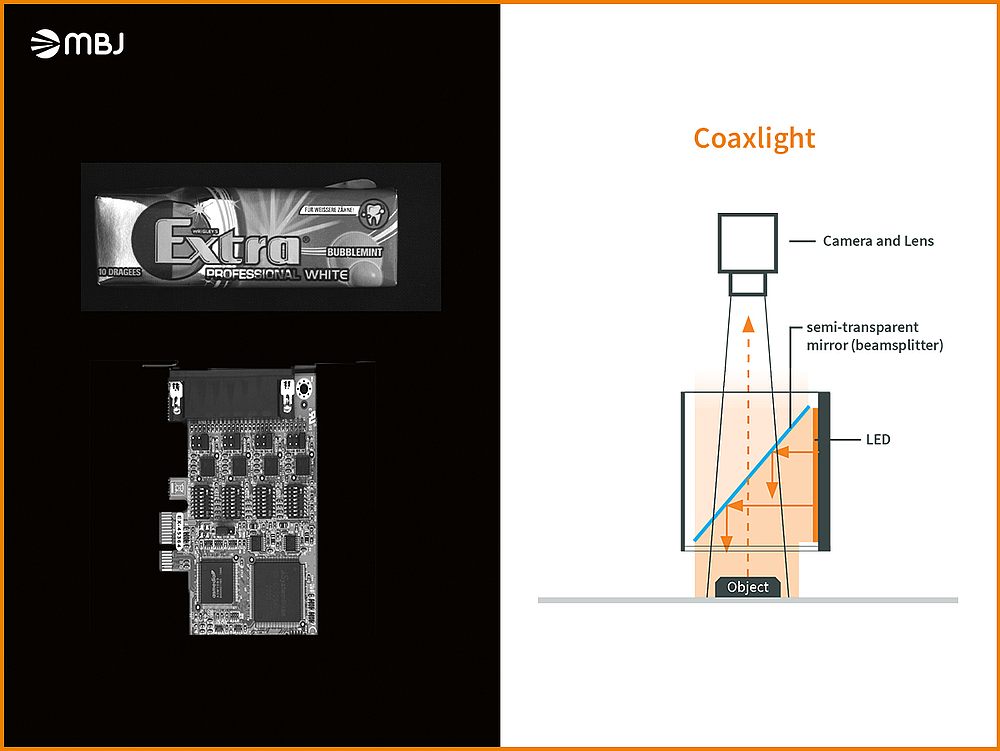

Coaxiallight

With coaxial illumination, the test object is illuminated homogeneously, without camera shadowing.

A unilaterally transparent mirror projects the diffuse light parallel to the optical axis directly into the imaging beam path of the camera. Note that each time the light passes through the mirror, about 50% of the light is absorbed and only about 25% of the light emission reaches the camera. This is typical for all coaxiallights and they are therefore mainly used for objects in rest position.

This type of illumination is suitable for highly reflective and shiny object surfaces. It is also well suited for transparent objects. Since the light is reflected perpendicularly, it is reflected away laterally when it hits unevenness, thus these appear dark in the camera.

- Diffuse, reflection-free illumination

- Illumination in objective axis without camera shadow

- Suitable for flat objects, surface structures, print image controls

It is important to know with coaxiallights that the camera's field of view (FOV) and the illuminated area do not correspond to the luminous area of the coaxiallight itself, but are usually smaller by just under a third to a half. This is due to the design of this type of illumination and applies equally to all coaxiallights. How much smaller this area is depends, among other things, on the distance of the illumination from the object (LWD = light working distance) and the camera from the luminous area/object. In general terms, it can be stated: The smaller the LWD, the larger the FOV.

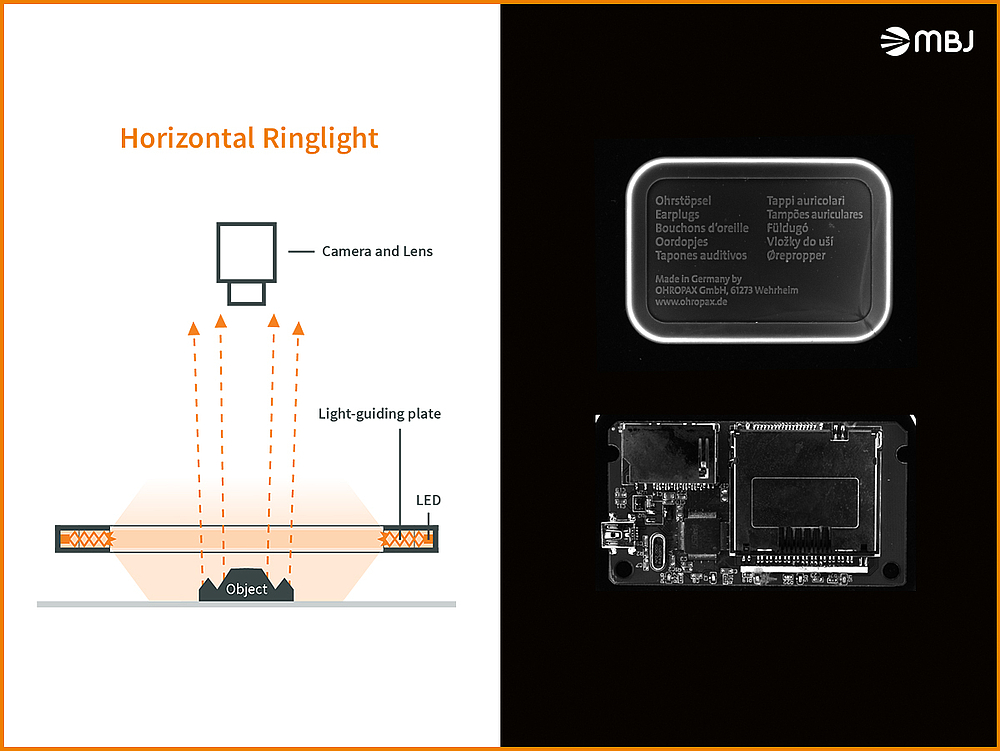

Horizontal Ringlight

With darkfield illumination, the test object is illuminated from the side at a flat angle. As a result, primarily the light hitting edges and oblique surfaces of the object is reflected into the camera. These surfaces appear bright in the image. Surfaces perpendicular to the camera appear dark. This type of illumination is very suitable to highlight surface defects - e.g. scratches that are invisible under normal light appear bright in the darkfield. In many cases, however, darkfield illumination is also used for diffuse illumination of barcodes. As a rule, darkfield lights are used with a very short working distance.

- Detection of surface defects

- Embossed or punched structures and edges

- Barcode inspection

Changing the working distance highlights different features of an object. In some cases, barlights are also used for dark field applications. The advantage of a horizontal ringlight is an uniform illumination from all sides

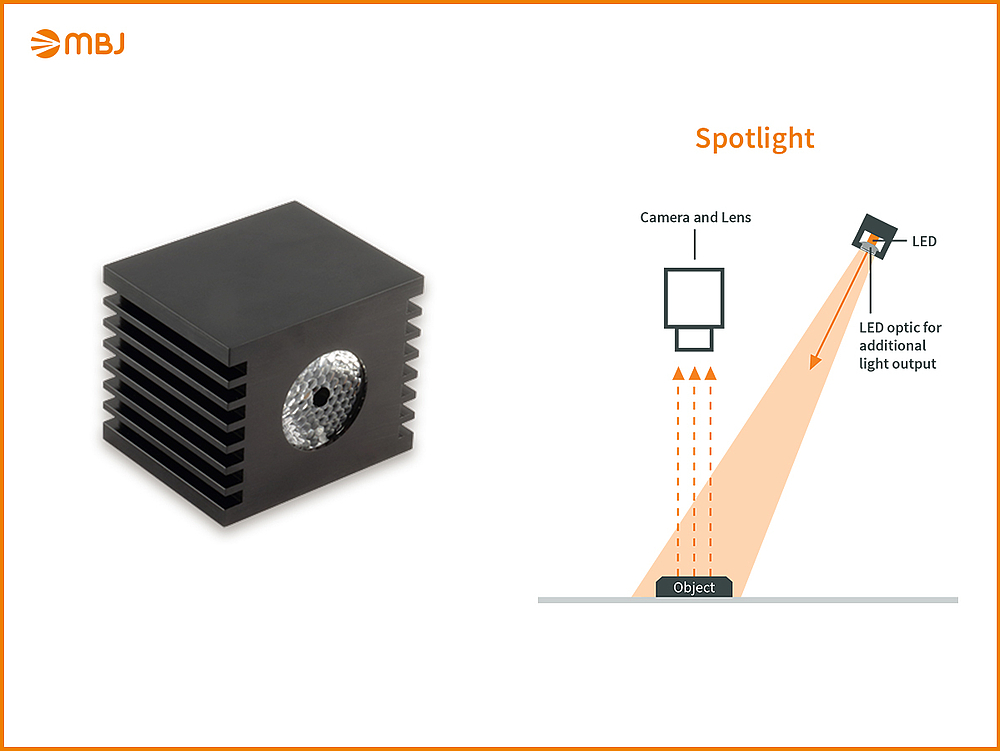

Spotlight

Spotlights are characterized by a very high brightness that is concentrated on a small area. Spots are used when large distances need to be bridged and/or only small areas/objects need to be illuminated. Another advantage is the small installation dimensions, which are advantageous in robotics, among other applications.

- Direct light emission

- High light output on a small area

- Suitable for limited space in the inspection system, larger working distances, smaller objects or detailed inspections, inspection within components

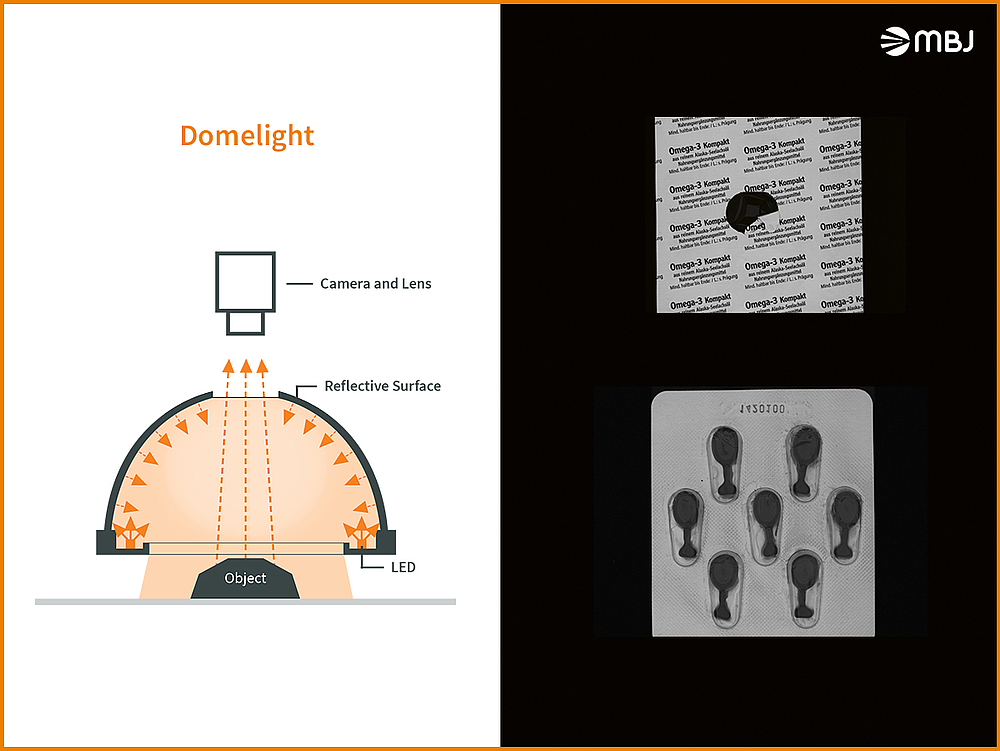

Domelight

The test objects are illuminated indirectly by reflecting the light on the inside of the white dome. The object is thus illuminated with maximum diffusion from all sides. The resulting almost shadow-free illumination is ideal when surface unevenness is to be compensated for, for example, in order to inspect printing. The camera records the object from above through the ring opening. This should be taken into account with highly reflective surfaces, as the camera opening may be visible on the test object.

- Almost shadow-free illumination from all angles

- Optical compensation of height differences

- Suitable for reflective objects, homogeneous illumination of uneven surfaces, reading and verification of two-dimensional patterns

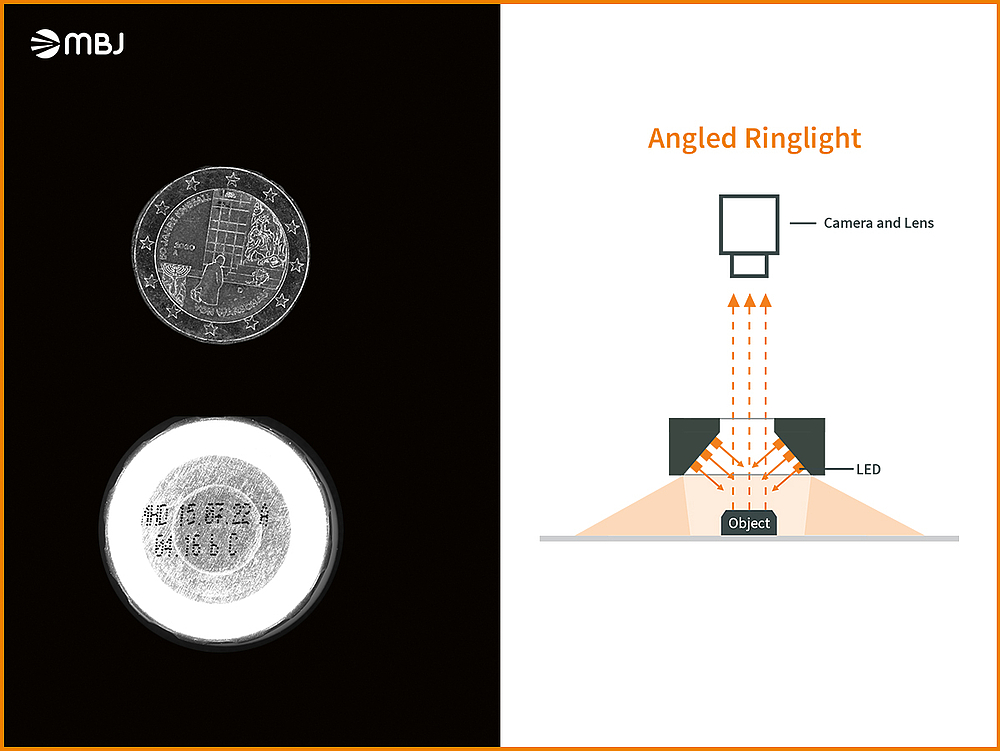

Angled Ringlight

With its 45° angle, the angled ring light is particularly suitable for surface analysis. Punched and relief structures in particular can be inspected well.

The lighting is mounted at a short working distance from the object, while the camera is mounted at a greater distance to avoid direct reflections.

In this way, slanted edges are highlighted and slight deepenings are illuminated.

4 Segment Ringlight

The 4-segment ring light has 4 segments that quarter the circular luminous area. Each of these segments can be independently controlled via its own channel using an external controller. Thus, test objects can be illuminated from different angles and three-dimensional properties can be evaluated. A typical application is the shape-from-shading/ photometric stereo application.

In shape-from-shading, an object is illuminated from different directions and one image is taken in each case. Pure 3D images (heights and depths) are calculated from the different light and shadow information using software. Even the slightest deviations in height can be represented. Interference factors such as reflections, prints or different surface textures no longer have a relevant influence on the image and a time-consuming adjustment of the lighting situation can thus be shortened.

3D shape determination - examples Inspection task:

- Braille on printed surfaces

- Inspection of relief structures/ embossing on objects

- Inspection of highly reflective objects

RGBW Ringlight

With 4 individually controllable channels each, the RGBW ring light simplifies tasks such as specific color assessments, while offering familiar advantages of ring lights such as the avoidance of hard object shadows or space-saving installation. Of course, accessories such as diffusers are also available for the RGBW ringlight. A real advantage over other RGB lighting is the true 4000 K white. In addition to the individual color channels in Red (625 nm), Green (535 nm) and Blue (465 nm), White is available as a separate channel and can therefore not only be generated additively. This ensures a uniform spectral distribution for white and provides additional brightness.

- Precise color control - detection of color deviations, color differences

- Fast adjustments to different color spaces possible

- True white can be controlled via its own channel - uniform spectral distribution and additional light intensity

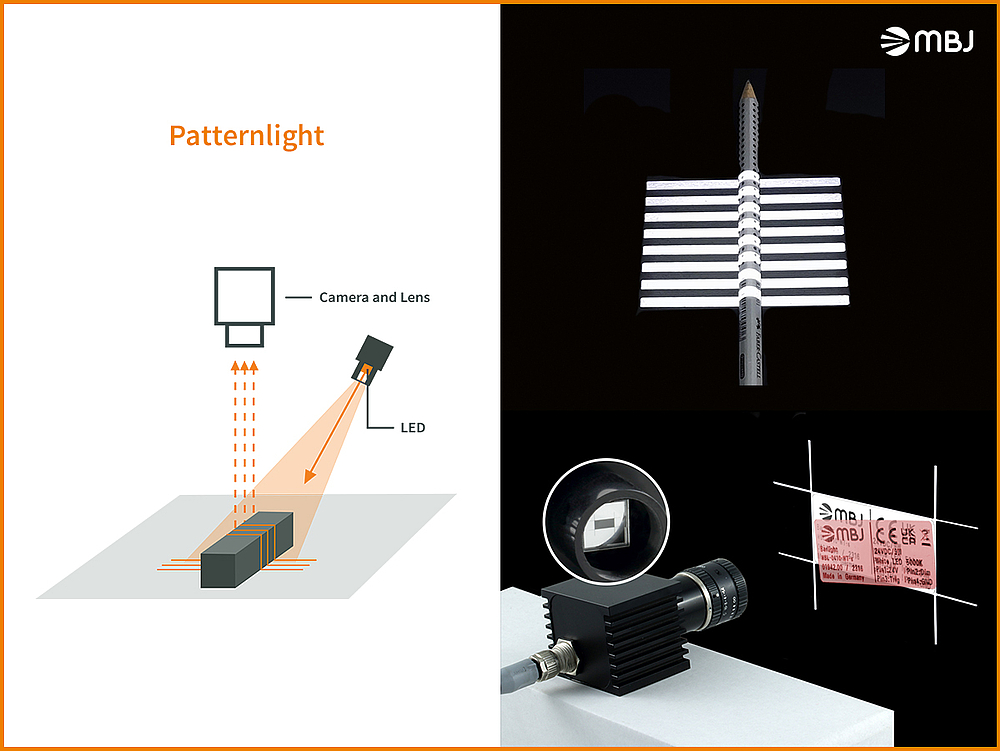

Patternlight

The Patternlight projects a pattern onto a surface. A powerful LED paired with a good lens ensures a high-contrast image high-contrast image.

With the projected pattern, a three-dimensional analysis can also be carried out on surfaces that are difficult to inspect. The camera is positioned at an angle to the surface, e.g. with low reflection or low contrast and the course and refraction of the pattern is analyzed using software. evaluated. A 3D image is created. Correct placement or filling of objects filling of objects can be verified so well.

The Patternlight shows its strength in combination with 2 cameras for

stereovision, ideal for pick and place applications, for example.

With customized patterns, the Patternlight can also be used as a positioning aid. The matching pattern, designed as a frame, is for simply manual placement projected onto an object.