The MBJ Checklist

Take advantage of our many years of experience in image processing and discuss your project with us.

From your specification we will propose a suitable brightness, illumination color, illumination angle and also illumination distance. The decision for continuous or flashed lighting also depends on this information.

All the information together ensures that the lighting is selected to exactly match your inspection task.

Send your information to MBJ

Use our lighting checklist to describe your inspection task. You can download it here, fill it out and send it back to us by e-mail.

What should be inspected?

For the selection of an illumination it is important to describe what is to be observed on the object. What change in object characteristics is expected during the inspection?

The more precise the description of the task, the more helpful for the selection of the appropriate lighting.

- Presence check (the object or parts of the object are missing / too much)

- Print image inspection / contamination (the color of the object changes)

- Measurement of objects (the size of the object changes)

- Contaminations / number check (additional objects are seen on or at the object)

- Level check / position determination for robots (parts of the object change their position)

Detailed object description

In addition, the object must also be described precisely. It is about size as well as the properties of the object.

The following questions will help:

- What material is the object made of (metal, plastic, glass, organic material)?

- What color is the object (red, green, blue, white, ...)?

- What properties does the object have (matte, reflective, mirroring, transparent...)?

- What is the shape of the object (flat, raised, semi-circular, slanted surfaces?

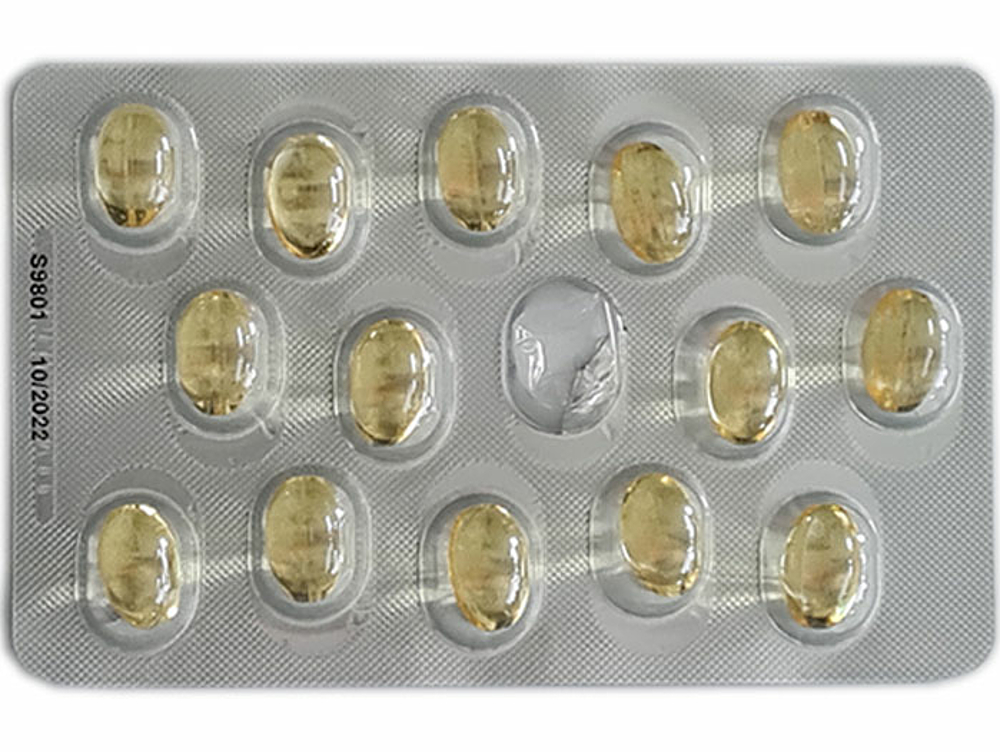

Example:

- Test object: capsules in packaging

- Material: oil

- Color: yellowish transparent

- Property: under reflective plastic

- Shape: raised, curved

The surroundings of the object

Here, the general conditions around the object are very important. They describe further influences that are very important for the choice of lighting.

Information that describes the object environment:

- What is the environment like (light, dark, reflective, patterned, wet, dusty)?

- Is the object always presented in the exact same position and orientation?

- Is the object still or moving when the picture is taken?

- How fast is it moving?

Finally, it is important to consider how much space the entire camera lighting system is allopwed to take up in order to be installed in a production facility.

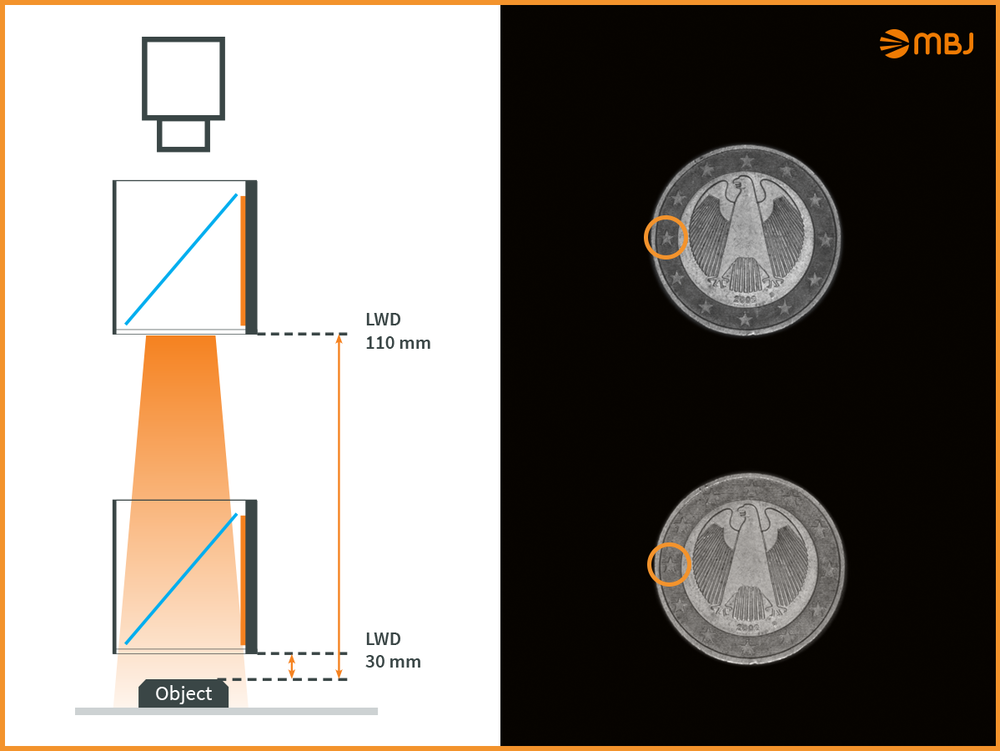

Variation of the working distances

The working distance of light to test object (light working distance, or LWD for short) has a considerable influence on the lights effect on the object when imaged with a camera. With the same illumination, different working distances can produce different qualitative results or even solve different inspection tasks.

Changes in the light object distance are particularly pronounced with angled lighting arrangements.

If the inspection result is not optimal or not stably repeatable, it can be helpful to change the LWD to achieve a higher contrast image.

As a general rule, dome, coaxial and horizontal ring lights show their advantages at a short working distance, while other lights such as the "normal" ring light or the High Power series require a somewhat larger LWD for homogeneous illumination of the working field.